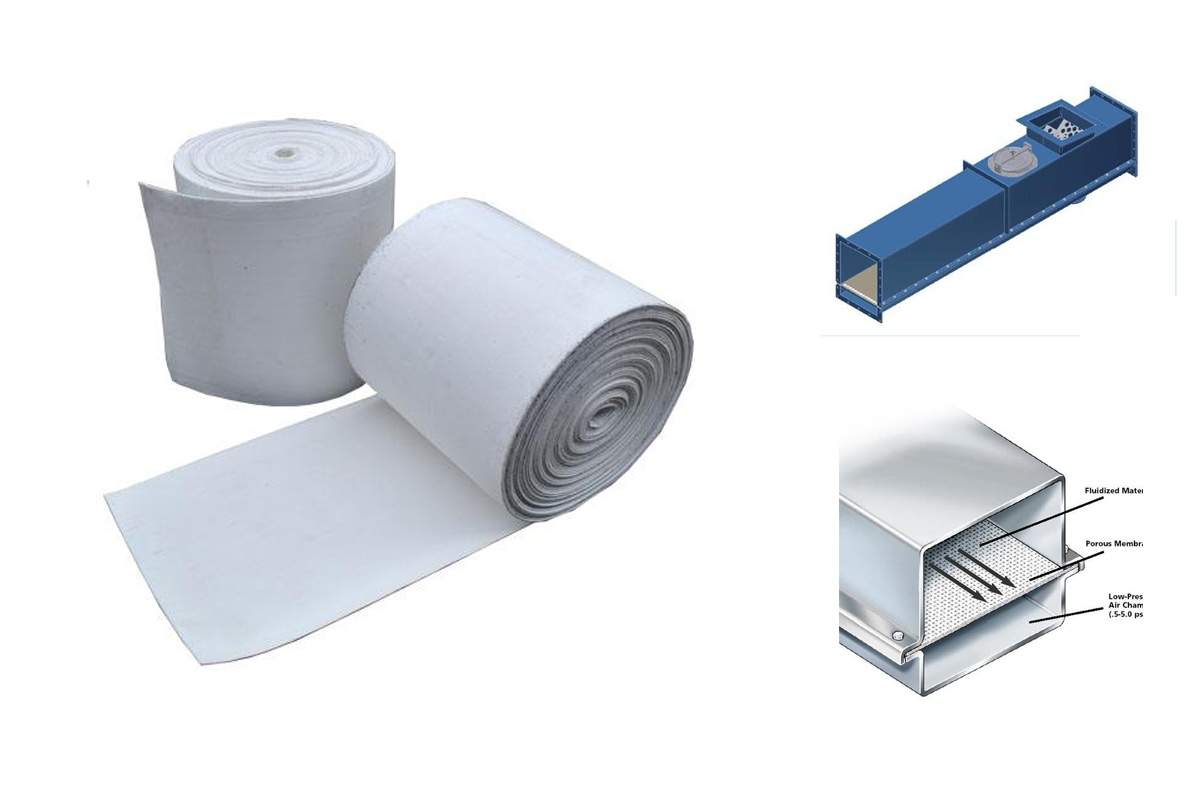

Air Slide Fabric is the core component of an air conveyor slotted trough. Made of synthetic fibers or polyester materials, it is installed as a breathable layer between the upper and lower trough housings. Its primary function is to inject compressed air through a high-pressure fan, fluidizing the material so that it slides down the sloped trough under gravity, achieving efficient and sealed powder material transport. It is mainly used in cement plants, power plants, metallurgy, and chemical industries, solving the horizontal or inclined transport of materials such as fly ash and alumina.

Performance Parameters of Air Slide Fabric

Made of synthetic fibers (such as polyester) or short-fiber materials, with a typical thickness of 4–8 mm, it is heat-resistant up to 150°C, wear-resistant, and has uniform air permeability.

Width: customizable

Length: 50m/roll, customizable

Main Application Scenarios of Air Slide Fabric

Cement Industry: Used for air-slotted trough transport of raw materials and cement powder, improving bottom-bin homogenization efficiency and reducing dust leakage.

Power & Metallurgy: Fly ash pneumatic transport in power plants; high-temperature resistance adapts to fluidized bed equipment.

Aluminum Industry: Ultra-concentrated alumina powder transport with corrosion-resistant design to extend service life.

Chemical & Environmental Protection: Handling granular materials (such as chemical raw materials); fully sealed structure reduces pollution risks.

As the core component of an air conveyor slotted trough, Air Slide Fabric is key to achieving efficient and sealed powder transport. Whether in cement, power, metallurgy, aluminum, or chemical and environmental protection industries, proper selection and installation of Air Slide Fabric can significantly improve transport efficiency, reduce dust emissions, and extend equipment service life.